Materials Outovation® Practice

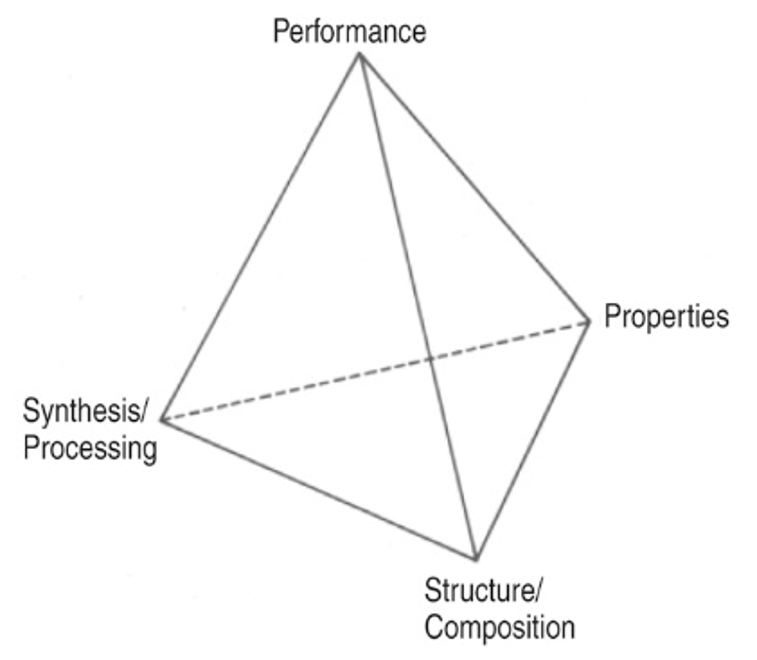

The Materials Outovation® practice focuses on businesses that can deliver growth by leveraging the composition, structure, properties, and processing of materials to provide customized performance in a product. The practice systematically seeks innovation by looking “outside” leveraging the process of Materials Outovation®.

Materials include metals, alloys, technical ceramics, glasses, high end polymers (fluoropolymers, silicones, aramids), composites (glass and carbon fiber), abrasives, adhesives, coatings, cements, concrete, and others. Companies utilize a customer co-development model – listening carefully to critical customer needs.

Processing techniques include melting, casting, rolling, extruding, co-injection molding, powder processing, welding, brazing, laser processing, CVD, PVD, and additive manufacturing.

Overview

Rakesh Kapoor: Materials Outovation® Practice Area Introduction

View our Materials Outovation® Practice at Edgewater Capital teaser

Select Focus Areas

View our Additive Manufacturing / 3D Printing teaser

View our Injection Molding teaser

View our Ceramic Membrane Filtration teaser

View our Specialty Polymer Compounding teaser

View our Microwave Devices, Components and Materials teaser

Media

Target Industries, End Markets, or Applications

Composites

Carbon fiber, aramid fiber, glass fiber, ceramic fibers, coatings on fibers

Aircraft structures – carbon fiber – exterior or interior; commercial or military

Composites for satellite systems and sub-assemblies

Glass fiber components for healthcare, transportation, and light industrial

Highly differentiated (only) composites for automotive

Ceramic Materials

Silicon carbide, titanium dioxide, thermoelectric materials, alumina, zirconia, boron-nitride

Diamond, graphene, carbon nanotubes

Substrate materials including ceramic/metal composites

Powders with unique coatings, morphology, properties

Abrasive products such as ceramics bonded with glass bonds (vitrified bonded) or diamond bonded with metals

Filtration

Systems for microfiltration and ultrafiltration

End industries including food & beverage, pharmaceutical processing, oil & gas, swimming pool, industrial wastewater, etc.

Ceramic membranes (alumina, silicon-carbide)

Coatings

Plasma spraying

Electroforming

Laser and electron beam coatings

PVD/CVD/ion implantation processing

Electronic Packaging Materials and Processes

Die attach

Wirebonding

Interconnect processing

Soldering

Thermal management solutions

Practice Leader: Dr. Rakesh Kapoor

rkapoor@edgewatercapital.com

Office: (216) 816-1799

Rakesh leads the Materials Outovation® practice at Edgewater Capital Partners. Rakesh spent 2 decades at Saint-Gobain ($50B multinational) serving in leadership roles in R&D, manufacturing, ventures, worldwide sales management, and in global general management – turning around an underperforming global engineered ceramics business. Rakesh has been a consultant for the C-suites of one of the largest primary metal companies; and for a mid-sized, fifth generation family held mining firm. Rakesh’s experiences emphasize growth by systematically looking “outside” the organization, a process he has trademarked as Materials Outovation®. Rakesh is a governance fellow of the National Association of Corporate Directors (NACD). Rakesh served on the advisory board of the MIT Materials Processing Center.

Rakesh holds a BTech in metallurgical engineering from IIT-Bombay and both MS and PhD degrees in Materials Science and Engineering from MIT.